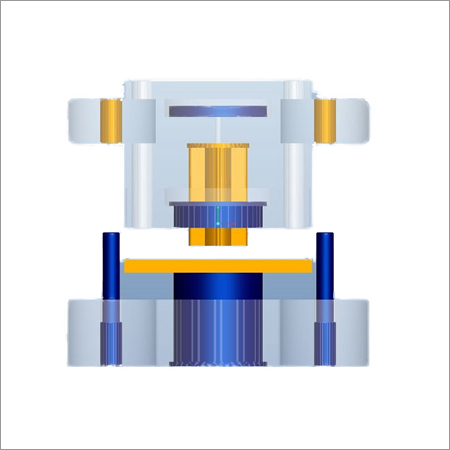

Multi Cavity Press Die

Price 10000 INR/ Unit

Multi Cavity Press Die Specification

- Life Span

- Over 1 million strokes

- Core Material

- Hardened tool steel

- Working Process

- Stamping, blanking, cutting, forming

- Mould Base

- High-grade steel, precision machined for stability and durability

- Tolerance

- 0.01 mm

- Material

- Alloy steel / Carbide

- Shaping Mode

- Press Die, multi-cavity configuration

- Punch Dies

- Multiple hardened punches for high cycle operation

- Die Head

- Multiple cavity die head for simultaneous production

Multi Cavity Press Die Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Telegraphic Transfer (T/T), Cheque

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Packaging Details

- as per requirements

- Main Domestic Market

- All India

About Multi Cavity Press Die

Tough construction and superior surface finish, these Multy Cavity Die are Hot dip galvanized to resist against rust. Our provided molds are insert is made by using best quality brass material and latest technology by our adroit professionals. It is widely used in electrical, automotive, and petrochemical industries to assemble various parts. The provided insert is offered in various sizes and shapes according to the customers requirements. This Multy Cavity Die can be purchased from us in bulk at the nominal market rate.

| Country of Origin | Made in India |

| Material | as per drawing |

| Size | as per drawing |

| Color | Bronze |

| Pattern Type | as per drawing |

| Usage/Application | Industrial |

Engineered for Durable High Output

Designed for mass production environments, our Multi Cavity Press Die leverages high-grade steel bases and hardened tool steel cores to deliver lasting performance over extended cycles. Progressive surface treatments minimize wear, and the modular design simplifies maintenance. This product is ideal for manufacturers seeking reliable, high-efficiency tooling for demanding stamping, blanking, and forming processes.

Precision at Its Core

Employing advanced CAD/CAM support and rigorous vacuum heat treatment, the die achieves 0.005 mm accuracy on critical features. Customizable cavity numbers, cutting angles, and die heads ensure that every solution fits your unique production specifications. Each die is carefully assembled and tested to guarantee stability, durability, and precise repeatability.

FAQs of Multi Cavity Press Die:

Q: How does the multi cavity configuration enhance production efficiency?

A: The multi cavity configuration allows the press die to produce multiple components in a single stroke. This arrangement significantly increases output, reduces cycle times, and is ideal for mass production in automotive, electronics, and hardware manufacturing.Q: What surface treatments are available, and how do they improve die lifespan?

A: Available surface treatments include nitriding, polishing, and custom coatings. These treatments enhance the dies wear resistance, minimize friction, and extend service life, allowing for reliable operation beyond 1 million strokes.Q: When should the dies cavity number or cutting angle be customized?

A: Customization of the cavity number or cutting angle is recommended when production requirements demand specific dimensions, shapes, or output rates. Adjusting these features ensures the die matches precise application needs and optimizes productivity.Q: Where is this multi cavity press die typically used?

A: This die is widely used in industries such as automotive, electronics, precision hardware, and components manufacturingwhere high output, precise tolerances, and durability are essential.Q: What is the process for maintaining and replacing parts in the modular die assembly?

A: The modular design allows for straightforward maintenance. Individual sections or worn parts can be replaced without dismantling the entire die, minimizing downtime and reducing maintenance costs.Q: What benefits does vacuum heat treatment provide to the die?

A: Vacuum heat treatment imparts superior hardness and uniformity to the die, enhancing wear resistance and stability throughout its operational lifespan. This ensures consistent performance even under intensive production cycles.Q: How accurate is this die, and what level of tolerance can be expected?

A: Critical features on the die are engineered to a dimension accuracy of up to 0.005 mm, with tolerances maintained at 0.01 mm. This high level of precision supports the manufacturing of intricate and reliable components.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Dies & Tools Category

Progressive Die

Price Range 10000.00 - 100000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Steel, Copper, Metal, Other, Rubber, Aluminum, Plastic, Tungsten Carbide

Mould Base : As per customer requirement, Steel, Brass

Working Process : Punching, Stamping, Bending

Compound Die

Price 5000 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Other, Alloy Steel

Mould Base : Steel, Precision Machined

Working Process : Other, Stamping, Cutting, Forming

Punching Tools and Dies

Price 5000 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Other, HighSpeed Steel, Carbide

Mould Base : High Precision Steel

Working Process : Other, Punching, Stamping, Cutting

Wire EDM Job Work

Price Range 1000.00 - 10000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Other, High Carbon Steel

Mould Base : Steel

Working Process : Other, Electrical Discharge Machining (EDM)

GST : 24AALFC4260B1ZX

|

CREATIVE ENGINEERING WORKS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry