Wire EDM Job Work

Wire EDM Job Work Specification

- Life Span

- Up to 6 Years

- Mould Base

- Steel

- Core Material

- Alloy Steel

- Working Process

- Electrical Discharge Machining (EDM)

- Tolerance

- 0.01 mm

- Material

- High Carbon Steel

- Shaping Mode

- Wire Cut

- Punch Dies

- Hardened Steel

- Die Head

- Customized

Wire EDM Job Work Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Telegraphic Transfer (T/T), Cheque

- Supply Ability

- 100 Units Per Day

- Delivery Time

- 1 Week

- Main Domestic Market

- All India

About Wire EDM Job Work

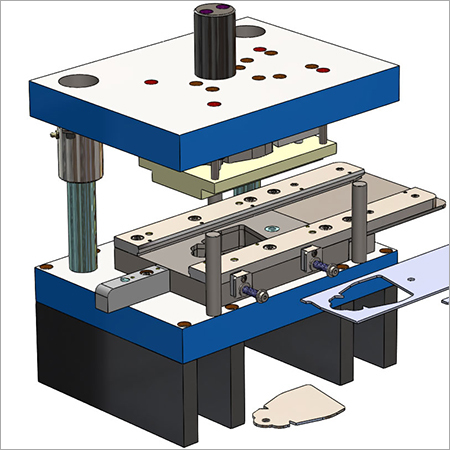

We offer Wire EDM Job Work service to our customer. This service is used for producing precision parts that match the dimensional tolerances of your designs within -/+ 0.005m. To design the patterns, we have EDM machining equipment and latest programming. Moreover, we can manufacture even the most complex parts with perfect accuracy and repeatability, whether you need short production runs, prototypes or quantities in the tens of thousands. Also, applications of this Wire EDM Job work to shape polycrystalline diamond tools have been reported.

| Service Duration | 1 - 4 days |

| Service Mode | Offline |

| Materials Used For Wire | Brass |

| Expert in Material Type | CNC Stainless Steel |

| Expertise in Industry | Automobile |

High Precision Wire EDM Solutions

We deliver fully automated Wire EDM job work with remarkable accuracy for industrial needs. Utilizing a reliable power supply of 380V, 50Hz and advanced wire cut shaping mode, our operations excel in manufacturing steel mould bases and alloy steel cores. Our customized approach results in optimal surface finishes and consistent quality, ensuring components perform dependably and meet stringent tolerance requirements.

Customization and Flexibility

Our services are tailored to your specifications, offering design flexibility for complex geometries and specialized material requirements. We accommodate a range of workpiece sizes up to 600 x 400 mm and deliver both matte and polished surface finishes, enhancing visual appeal and functionality. With on-site and off-site service locations, convenience and commitment to your schedule are guaranteed.

Long-lasting Performance

By employing high carbon steel and hardened steel for punch dies and components, our Wire EDM solutions maximize durability. Each product is engineered for longevity, with a lifespan of up to six years. Strict quality controls and advanced EDM technology ensure parts remain reliable in demanding industrial environments, supporting uninterrupted manufacturing cycles.

FAQs of Wire EDM Job Work:

Q: How does the Wire EDM job work process ensure high precision in manufacturing?

A: Our Wire EDM services utilize advanced Electrical Discharge Machining (EDM) technology, allowing us to achieve tolerances as tight as 0.01 mm. The fully automated operation and precise control mechanisms ensure each component meets exact specifications required for tool and die making or precision part applications.Q: What options are available for surface finish and material selection?

A: We provide both matte and polished surface finishes, selectable according to customer preference. Materials are chosen based on application needs, including mould bases made from steel, core material from alloy steel, and punch dies from hardened or high carbon steel for enhanced durability and performance.Q: Where can the Wire EDM job work service be provided?

A: Our Wire EDM job work is available both on-site at client locations and off-site at our production facility. We cater to customers across India, offering flexibility in service delivery to match project requirements and schedules.Q: What is the maximum size and cutting speed for workpieces processed via Wire EDM?

A: We can handle workpieces up to 600 x 400 mm in size, with cutting speeds ranging from 60 to 180 mm/min. These capabilities ensure efficient processing of large and complex components while maintaining high quality standards throughout production.Q: What kind of customization is offered and how does it benefit my project?

A: Our Wire EDM services are fully customizable, including design adaptations, surface finish choices, and material selections. This flexibility supports the creation of specialized components that meet unique project specifications, ensuring optimal performance and satisfaction.Q: When should I consider Wire EDM job work for my manufacturing needs?

A: Wire EDM job work is ideal for projects requiring intricate shapes, high precision, and demanding tolerancessuch as in tool and die making and industrial precision parts. It is particularly recommended when traditional machining methods cannot achieve the required accuracy or surface quality.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Dies & Tools Category

Progressive Die

Minimum Order Quantity : 1 Unit

Working Process : Punching, Stamping, Bending

Tolerance : 0.001 Millimeter (mm)

Life Span : 1000000

Material : Steel, Copper, Metal, Other, Rubber, Aluminum, Plastic, Tungsten Carbide

Punching Tools and Dies

Price 5000 INR / Unit

Minimum Order Quantity : 1 Unit

Working Process : Other, Punching, Stamping, Cutting

Tolerance : 0.01 mm

Life Span : Up to 300,000 Punches

Material : Other, HighSpeed Steel, Carbide

Compound Die

Price 5000 INR / Unit

Minimum Order Quantity : 1 Unit

Working Process : Other, Stamping, Cutting, Forming

Tolerance : 0.01 mm

Life Span : 50,000 100,000 Cycles

Material : Other, Alloy Steel

Press Dies Tools

Price 5000 INR / Unit

Minimum Order Quantity : 1 Unit

Working Process : Other, Sheet Metal Forming

Tolerance : 0.005 mm

Life Span : High durability

Material : Highstrength Alloy, Other

GST : 24AALFC4260B1ZX

|

CREATIVE ENGINEERING WORKS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry