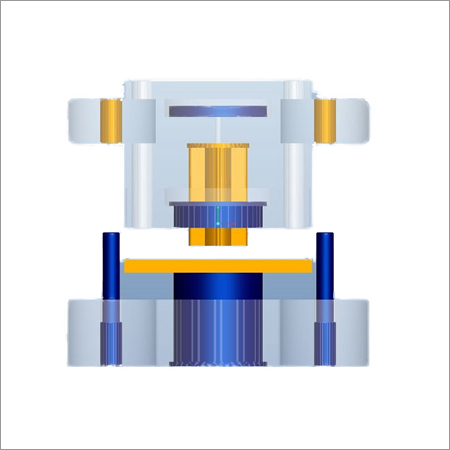

Punching Tools and Dies

Price 5000 INR/ Unit

Punching Tools and Dies Specification

- Core Material

- Alloy Tool Steel

- Mould Base

- High Precision Steel

- Working Process

- Punching, Stamping, Cutting

- Tolerance

- 0.01 mm

- Life Span

- Up to 300,000 Punches

- Material

- High-Speed Steel, Carbide

- Shaping Mode

- Compression Mould

- Punch Dies

- Tungsten Carbide / Hardened Steel

- Die Head

- Custom Engineered

Punching Tools and Dies Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Telegraphic Transfer (T/T), Cheque

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Packaging Details

- as per requirements

- Main Domestic Market

- All India

About Punching Tools and Dies

We have a top of the line Punching Tools tool shop that enables us to excel at progressive die stamping. We are able to customize progressive die designs as per customer specifications as we have the ability to manufacture in-house. We have successfully developed complex press tool profiles with 45 stages, and have the capability to design, develop and manufacture profiles of even higher complexity.

Progressive dies are used for high-volume manufacturing and are fashioned to operate at high speeds. Eigen produces high-quality, reliable and cost-effective progressive dies. We have the proficiency and technological know how to fabricate, quality test and produce robust progressive tools that tackle a broad spectrum of production challenges. The key to our success is our superb craftsmanship. We routinely work with aerospace, defense, electrical and electronic industries, in addition to industrial engineering, automotive and ancillary units as well as consumer durable industries.

Eigen recommends progressive tool stamping for tooling with insert construction to facilitate on-the-double component replacement imperative in high-wear manufacturing processes as well as for intricate designs that require coiling and varying material thicknesses in the final outcome.

Punching Tools and Dies are essential for metalworking methods which are designed for executing the tasks of coining, bending, punching, and several other manners of modifying metal in a desired end part shape. These provide you the most effective material alternative for production of your parts. These allow the users to create parts with several geometries within a single tool. The continuous material feed utilized in the process of these dies enable long operations. Punching Tools and Dies enable vast flexibility in material changes and tooling accommodations in a much shorter time. These enable the users to create parts with several geometries within an individual tool.

| Feature | High Precision |

| Size | 25 mm |

| Surface Finish | Polished |

| Country of Origin | Made in India |

| Material | Tool Steel |

Superior Surface Treatments for Longevity

The tools and dies undergo advanced surface treatments such as polishing, nitriding, and heat treatment. These processes create a mirror-polished finish, reduce friction during use, and dramatically increase wear resistance and overall lifespan, even in high-temperature industrial applications. Customers can also opt for custom coatings tailored to specific requirements.

Customizable Precision for Any Application

Available with a diameter range from 0.8 mm to 60 mm and handling sheet thickness up to 10 mm, these tools can be tailored to unique industrial needs. Customization extends to dimension, shape, edge profile, mounting flange, and protective coating. All products maintain 0.01 mm tolerance, ensuring precise, repeatable results with every press.

FAQs of Punching Tools and Dies:

Q: How can I customize punching tools and dies to suit my application requirements?

A: You can customize these punching tools and dies by specifying your required size, shape, and coating preferences. Options include different diameters, thickness capacities, custom flange mountings, and edge profiles. Our team will assist in engineering the perfect solution, whether you need tungsten carbide, hardened steel, or additional surface treatments.Q: What materials and treatments contribute to the durability of your punching tools?

A: Our tools are manufactured from high-speed steel, carbide, and alloy tool steel. Enhanced by heat treatment, nitriding, and mirror polishing, these materials reach a hardness of HRC 58-62, ensuring sharp, wear-resistant cutting edges and a long operational lifespan, even with frequent industrial use.Q: When are these tools suitable for use in metal sheet fabrication?

A: These tools and dies are ideal for use in metal sheet punching and industrial fabrication wherever precision, durability, and high output are required. With the ability to perform under temperatures up to 250C and maintain 0.01 mm tolerance, they are perfectly suited to demanding sheet metal working operations.Q: Where are your punching dies and tools typically used, and what industries benefit from them?

A: Our tools are widely used in industrial fabrication, automotive, electrical enclosures, appliance manufacturing, and general metalworking sectors. Manufacturers, exporters, and service providers throughout India and internationally utilize them for the efficient, high-quality processing of metal sheets.Q: What is the process for mounting and using these die sets?

A: Each die set can be supplied with standard or custom-engineered flanges for easy integration into your existing presses or stamping lines. The tools are packaged in protective plastic cases or wooden boxes for safe transport, ensuring they arrive ready for immediate use in your manufacturing process.Q: What benefits do polished and treated punching tools offer over untreated alternatives?

A: Polished, nitrided, and heat-treated tools offer a significantly longer service life and superior performance. Their smooth, mirror-like surfaces and enhanced hardness reduce downtime, minimize maintenance, and improve edge sharpness, providing greater productivity and consistent results in high-volume operations.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Dies & Tools Category

Progressive Die

Price Range 10000.00 - 100000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Shaping Mode : Extrusion Mould

Working Process : Punching, Stamping, Bending

Material : Steel, Copper, Metal, Other, Rubber, Aluminum, Plastic, Tungsten Carbide

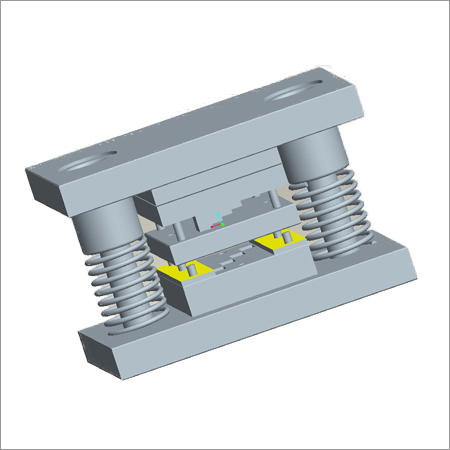

Compound Die

Price 5000 INR / Unit

Minimum Order Quantity : 1 Unit

Shaping Mode : Other, Compound Die

Working Process : Other, Stamping, Cutting, Forming

Material : Other, Alloy Steel

Blanking Dies

Price 5000 INR / Unit

Minimum Order Quantity : 1 Unit

Shaping Mode : Other, Press Mould

Working Process : Other, Blanking and Punching

Material : Other, Tool Steel

Wire EDM Job Work

Price Range 1000.00 - 10000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Shaping Mode : Other, Wire Cut

Working Process : Other, Electrical Discharge Machining (EDM)

Material : Other, High Carbon Steel

GST : 24AALFC4260B1ZX

|

CREATIVE ENGINEERING WORKS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry