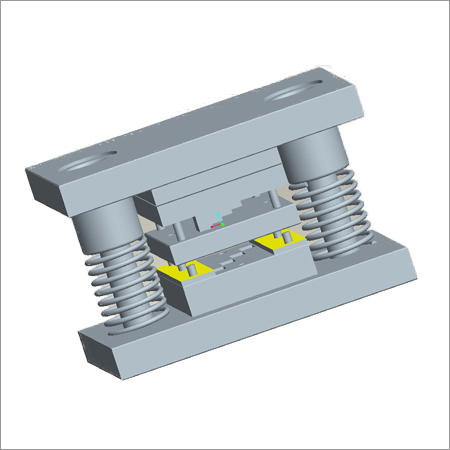

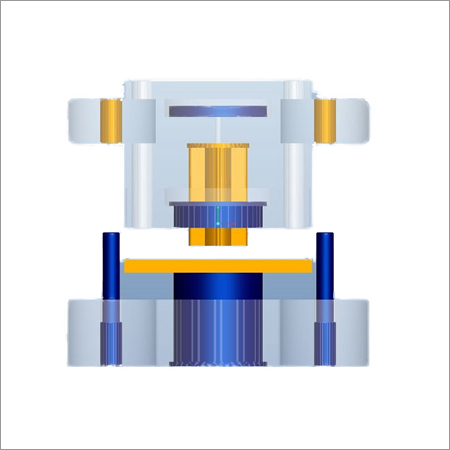

Compound Die

Price 5000 INR/ Unit

Compound Die Specification

- Tolerance

- 0.01 mm

- Core Material

- Tool Steel

- Working Process

- Stamping, Cutting, Forming

- Mould Base

- Steel, Precision Machined

- Life Span

- 50,000 - 100,000 Cycles

- Material

- Alloy Steel

- Shaping Mode

- Compound Die

- Punch Dies

- High-Speed Steel Inserts

- Die Head

- Multi-Part Construction

Compound Die Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Telegraphic Transfer (T/T), Cheque

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Packaging Details

- as per requirements

- Main Domestic Market

- All India

About Compound Die

We have quality tested Compound Dies that help us to excel at progressive die stamping. These tools are used for high volume manufacturing and known to operate at high speed. Our tools are appreciated for being durable, qualitatively flawless, strong & high performing. They apply force from diverse directions on metals with the use of hybrid compound dies. There is a large scale demand for these tools all over India. To meet all these demands, we provide Compound Dies to our customers in different sizes and shapes.

Compound Dies are offered with process where the die detaches or blanks the part from a steel strip. These are capable to perform multiple punches or cuts in one stroke, as comparison to multiple strokes. These cost effective methods for stamping medium to high volume parts can help in maintaining labor as well as die costs reduced. Employed to stamp simpler flat parts, the feed pace of the the offered product can be determined by their size. Typically, the dies do not need a cut-off station as the parts are emptied through the strip. These are added to assist in managing the scrap material.

| Brand | Creative Engineers |

| Hardness | 62-67 HRC |

| Material | HSS |

| Usage | Stamping Dies |

| Country of Origin | Made in India |

| Usage/Application | Power Press |

Tailored for Precision and Durability

Designed for rigorous sheet metal fabrication, our compound dies offer custom dimensions and superior surface finishes. Utilizing induction-hardened tool and alloy steels, they meet demanding ISO 9001:2015 standards, resulting in robust performance and extended operational life. The multi-part construction and high-speed steel punch inserts guarantee consistent, high-accuracy results across stamping, cutting, and forming applications.

Effortless Integration and Maintenance

These dies are engineered for direct press machine integration, allowing for rapid installation and easy replacement of components. The use of precision machining ensures exact fit and function, while our design facilitates swift maintenance. This keeps downtime minimal and productivity high, making our product ideal for dynamic fabrication environments.

FAQs of Compound Die:

Q: How do I choose the right compound die specifications for my sheet metal fabrication needs?

A: Consider factors such as material type, sheet thickness, and desired stamping or forming processes. Our dies offer customizable dimensions and tolerances of 0.01 mm and are compatible with a range of press machines. We provide expert advice to ensure your requirements are matched perfectly.Q: What surface finishes are available for your compound dies, and why are they important?

A: Our compound dies are available with polished or ground surface finishes. These finishes enhance the quality of stamped parts, reduce friction during operation, and help extend die life by minimizing wear and tear.Q: When should die parts be replaced, and is maintenance complicated?

A: Die parts should be replaced when you notice decreased cutting precision or surface wear after prolonged usetypically between 50,000 and 100,000 cycles. Replacement is straightforward, as our design supports easy access and simple replacement of individual components.Q: Where can your compound dies be installed, and are they compatible with all press machines?

A: Our dies are designed for direct installation into most standard press machines used in sheet metal fabrication. Custom dimensions ensure compatibility with different machine models as per your operational needs.Q: What benefits do induction-hardened, high-precision dies offer compared to standard tooling?

A: Induction-hardened dies, rated HRC 5862, deliver superior longevity and consistent accuracy, supporting extended production runs. Their robust construction minimizes wear, maintains tight clearances, and reduces the frequency of maintenance, which translates to cost savings and improved production efficiency.Q: How does the progressive or compound die design enhance the fabrication process?

A: These die types streamline multiple fabrication stepscutting, stamping, and forminginto one process, increasing efficiency and consistency. The multi-part die head design further enables precise, repeatable output for high-volume production.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Dies & Tools Category

Progressive Die

Price Range 10000.00 - 100000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Mould Base : As per customer requirement, Steel, Brass

Tolerance : 0.001 Millimeter (mm)

Material : Steel, Copper, Metal, Other, Rubber, Aluminum, Plastic, Tungsten Carbide

Punching Tools and Dies

Price 5000 INR / Unit

Minimum Order Quantity : 1 Unit

Mould Base : High Precision Steel

Tolerance : 0.01 mm

Material : Other, HighSpeed Steel, Carbide

Blanking Dies

Price 5000 INR / Unit

Minimum Order Quantity : 1 Unit

Mould Base : Steel

Tolerance : 0.005 mm

Material : Other, Tool Steel

Wire EDM Job Work

Price Range 1000.00 - 10000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Mould Base : Steel

Tolerance : 0.01 mm

Material : Other, High Carbon Steel

GST : 24AALFC4260B1ZX

|

CREATIVE ENGINEERING WORKS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry