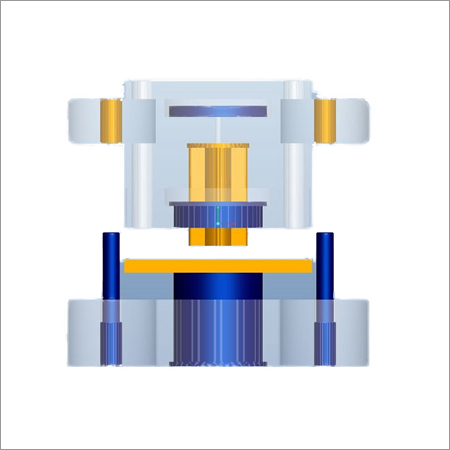

Blanking Dies

Price 5000 INR/ Unit

Blanking Dies Specification

- Life Span

- Up to 1 million strokes

- Core Material

- High-Speed Steel (HSS)

- Mould Base

- Steel

- Tolerance

- 0.005 mm

- Working Process

- Blanking and Punching

- Material

- Tool Steel

- Shaping Mode

- Press Mould

- Punch Dies

- Carbide Tipped

- Die Head

- Alloy Steel

- Hardness

- 58-62 HRC

- Customization

- Available

- Surface Finish

- Polished

- Color

- Silver / Grey

- Packaging Type

- Wooden Box

- Application

- Metal Sheet Cutting

- Capacity

- 5-100 tons

- Processing Type

- CNC Machined

- Product Type

- Progressive Die

Blanking Dies Trade Information

- Minimum Order Quantity

- 1 Unit

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Packaging Details

- as per requirements

- Main Export Market(s)

- Australia, South America, Middle East, Western Europe, Central America, Asia, Eastern Europe, North America, Africa

- Main Domestic Market

- All India

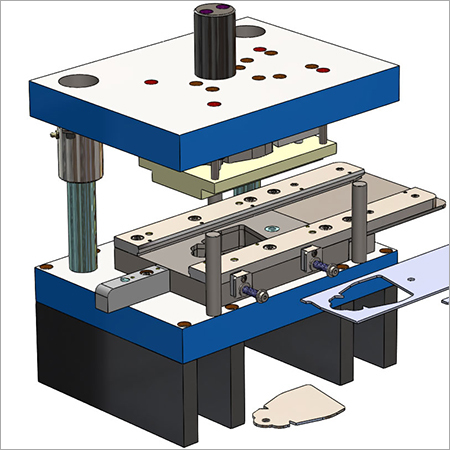

About Blanking Dies

We are counted as famous company in this domain for manufacturing & supplying quality approved Blanking Die And Tools. Our team of highly trained and skilled professionals uses advance techniques and premium grade aluminium metal in order to manufacture this die with perfection. Ideal for fabrication of both medium & low volume products, this die helps in providing defect free shape to various components. Moreover, we have successfully developed tough press tool profiles with 45 stages, and have the ability to design, develop & manufacture profiles of even higher complexity.

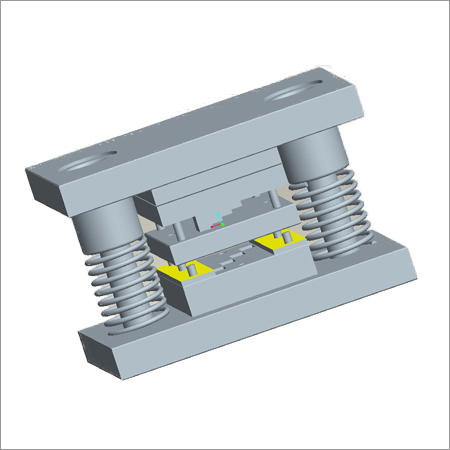

We have a top of the line blanking die and tool shop that enables us to excel at progressive die stamping. We are able to customize progressive die designs as per customer specifications as we have the ability to manufacture in-house. We have successfully developed complex press tool profiles with 45 stages, and have the capability to design, develop and manufacture profiles of even higher complexity.

Progressive dies are used for high-volume manufacturing and are fashioned to operate at high speeds. Eigen produces high-quality, reliable and cost-effective progressive dies. We have the proficiency and technological knowhow to fabricate, quality test and produce robust progressive tools that tackle a broad spectrum of production challenges. The key to our success is our superb craftsmanship. We routinely work with aerospace, defense, electrical and electronic industries, in addition to industrial engineering, automotive and ancillary units as well as consumer durable industries.

Eigen recommends progressive tool stamping for tooling with insert construction to facilitate on-the-double component replacement imperative in high-wear manufacturing processes as well as for intricate designs that require coiling and varying material thicknesses in the final outcome.

Offered Blanking Dies are rendered with advance techniques and best production processes. These are made with premium grade aluminium metal and are perfect for fabrication of both low & medium volume products. These assist in providing defect free form to different components. Furthermore, these have ability to manufacture, design & create profiles of even higher complexity. These enable the users to excel in progressive die stamping in compliance with customer specifications. Utilized for high-volume production, these dies can be operated at high speeds. These high-quality Blanking Dies are reliable and can be demanded in defense, industrial engineering, automotive, electrical and electronic industries, aerospace, consumer durable industries etc.

| Brand | Creative Engineers |

| Hardness | 62-67 HRC |

| Material | HSS |

| Usage | Stamping Dies |

| Country of Origin | Made in India |

| Usage/Application | Power Press |

Exceptional Durability and Precision

Designed for high-performance environments, our blanking dies feature hardened tool steel and carbide-tipped punch dies, ensuring reliable operation and a lifespan of up to one million strokes. Precision CNC machining keeps tolerances tightly controlled, making these dies suitable for intricate and repetitive metal sheet cutting.

Flexible Customization and Application

Available in customizable sizes and specifications, our progressive dies are tailored to fit various metal sheet cutting requirements. With supported press capacities from 5 to 100 tons, these dies are widely used across automotive, appliance, and general fabrication industries, providing outstanding flexibility for client-specific needs.

Comprehensive Support and Service

As a leading exporter, manufacturer, and service provider from India, we offer support throughout product selection, installation, and maintenance. Our high-quality packaging and professional after-sales service ensure that customers experience minimal downtime and consistent product performance.

FAQs of Blanking Dies:

Q: How are these blanking dies manufactured for precision and durability?

A: These dies are produced through advanced CNC machining, employing premium tool steel and high-speed steel (HSS) for the base and core. The die head uses alloy steel while punch dies are carbide-tipped, collectively ensuring a hardness of 58-62 HRC, extended lifespan, and a close tolerance of 0.005 mm.Q: What applications are suitable for these progressive blanking and punching dies?

A: They are specifically designed for metal sheet cutting in industries such as automotive, electronics, appliances, and general fabrication. Their ability to handle up to 100-ton press capacities makes them ideal for high-volume, repetitive stamping operations.Q: When should I consider customization for my die requirements?

A: Customization is recommended when specific dimensions, shapes, or production volumes divergent from standard offerings are needed. Our engineering team can tailor the design, material composition, and processing technique to match your unique application and performance expectations.Q: Where can I get these blanking dies and support services?

A: We are a prominent exporter, manufacturer, and supplier based in India. Orders and service requests can be initiated directly through our sales team, and we provide international shipping with robust packaging in wooden boxes to ensure product safety during transit.Q: What is the main process involved with these dies?

A: These dies operate using a progressive die process, which allows multiple blanking and punching operations in a single press cycle. This increases efficiency, maintains tight tolerances, and reduces material waste, making them suitable for large-scale production.Q: How does using this product benefit my manufacturing operation?

A: Using our dies ensures exceptional repeatability, high output, and reduced downtime due to their durable construction and long lifespan. The precision and robust material selection lead to minimal maintenance requirements and consistently high-quality finished parts.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Dies & Tools Category

Progressive Die

Minimum Order Quantity : 1 Unit

Shaping Mode : Extrusion Mould

Tolerance : 0.001 Millimeter (mm)

Working Process : Punching, Stamping, Bending

Multi Cavity Press Die

Price 10000 INR / Unit

Minimum Order Quantity : 1 Unit

Shaping Mode : Other, Press Die, multicavity configuration

Tolerance : 0.01 mm

Working Process : Other, Stamping, blanking, cutting, forming

Punch Dies : Multiple hardened punches for high cycle operation

Compound Die

Price 5000 INR / Unit

Minimum Order Quantity : 1 Unit

Shaping Mode : Other, Compound Die

Tolerance : 0.01 mm

Working Process : Other, Stamping, Cutting, Forming

Punch Dies : HighSpeed Steel Inserts

Press Dies Tools

Price 5000 INR / Unit

Minimum Order Quantity : 1 Unit

Shaping Mode : Other, Compression Molding

Tolerance : 0.005 mm

Working Process : Other, Sheet Metal Forming

Punch Dies : Precision Engineered Punch Dies

GST : 24AALFC4260B1ZX

|

CREATIVE ENGINEERING WORKS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry